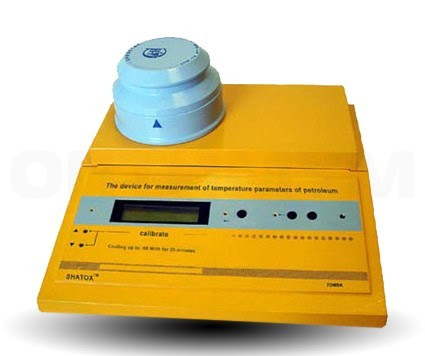

Oil Product Low-temperature Characteristics Meter - OPLCM SX-800 SX-850 SX-900K SX-900A

Produk Detail

BINTANG INSTRUMENT : HP /WA : 081362449440 , eMail : b081362449440@yahoo.com ( Mr Jonathan )

Oil Product Low-temperature Characteristics Meter - OPLCM

| Modifications | |

|---|---|

| Determination of motor oil freezing temperature and diesel fuel with additives ; | |

| Determination of dynamic viscosity within the temperature range from +50C to -50C; | |

| Determination of crystallization temperature of aviation kerosene down to -70C. | |

| Crystallization temperature of antifreeze | |

OPLCM is intended for crystallization temperature measurement of the jet-plane fuel, diesel fuel cloud-point and freezing temperature measurement, motor oil freezing temperature and dynamic viscosity measurement in the laboratory and field conditions.

OPLCM is a new generation instrument, and depending on modification can be used for fuel and oil quality control. Each model is unique in itself, and all methods of analysis and arrangement are patented. The common feature for all instrument modifications is cryostat with cooling down to minus 60C (diesel fuel and motor oil) and down to minus 70C during analysis of jet fuel. The instrument has LC display which shows the examination process in real time mode. The instrument's case is ergonomic and can resist any oil product or solvent.

Advantages of the OPLCM instrument

- OPLCM is an instrument for rapid analysis of diesel fuel, and oil as well as for aviation kerosene in laboratory and factory environment. It is powered from 220V power line.

- Low temperature characteristics of aviation kerosene is determined with a laboratory test called "crystallization temperature detection". During the course of the test the fuel sample is cooled down until paraffin OPLCMs are formed and detected with the optical monitoring system. The accuracy of the parameter is very important for safety of the plane flights.

- Temperature of motor oil freezing is detected using special sensor that records the moment of sample transition from solid state into liquid. In order to do that the sample is being cooled down until complete solidness, and after that the sensor system is turned on.

- In the same way to aviation kerosene, the principal of cloud point temperature determination for diesel fuel is based on short-range infrared transillumination of the sample.

- Dynamic viscosity is determined by rotation viscosimeter.

- The process information is shown on the liquid OPLCM display in all modifications of the instrument.

- The microprocessor processes the results of measurement.

- The external cryostat is not required, the built-in cryostat is made on Peltiye elements. Toxic coolants and dispensable are not used. The radiator of Peltiye element is cooled with water.

- The major goal of any laboratory is to provide the highest level of measurement results reliability. In order to increase the accuracy of temperature measurement the user can input correction data into nonvolatile memory.

- Instruments of OPLCM series meet all ISO 9001 requirements.

Specifications of the OPLCM instrument

| № | Parameter description | Value |

|---|---|---|

| 1. | Sample volume, ml |

1,9+0,1 |

| 2. | Limit of cooling temperature, C | - 70 |

| 3. | Inaccuracy of cloud point temperature detection, degrees C | 1 |

| 4. | Inaccuracy of freezing temperature detection, degrees C (type of detection - mechanical) | 2 |

| 5. | Inaccuracy of dynamic viscosity detection, % | 3 |

| 6. | Maximum time of test, min | 25 |

| 7. | Minimal time between tests, min | 15 |

| 8. | Compliance with test method | ASTM D 2386, D 5901, ASTM D 4684, ISO 3013 |

| 9. | Working conditions(temperature) of the instrument, C | from +15 to +35 |

| 10. | Dimensions, mm | 240х240х140 |

| 11. | Weight, kg | max 3 |

| 12. | Mean-time-between-failures, hours | not less than 1000 |

Major advantages

-

Test process is completely automated

-

The instrument has high speed and accuracy of measurement

-

The instrument is compact

.

.

.

.

-

Jual Infrared Belt Tension Meter SK500 Sanker Infrared Tension meter Sanker Indonesia

-

Lohan Instrument Indonesia Distributor Lohan Indonesia Water Quality Test Equipment

-

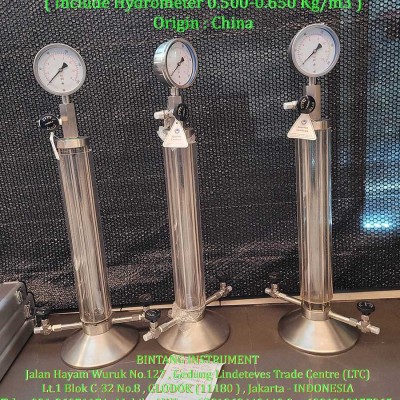

Pressure Hydrometer Cylinder Pressure Hydrometer Cylinder ASTM D1657 and ISO 3993 ready stock murah

-

Thermometer ASTM Amarel ASTM 3C 5C 36C 37C 41C 60C 64C 88C 92C 113C 99F

-

081362449440 Jual SIBATA SCIENTIFIC TECHNOLOGY LTD Indonesia Distributor

-

081362449440 Jual Alat Ukur texture Makanan Texture Tester TEX-100N Texture tester Tex-200N

-

Tank Thermometer Petroleum Gauging Thermometer Thermometer minyak Thermometer Thermoprobe TP7D

-

TSS Meter Murah TSS Meter Akurat TSS Meter terbaru Meteran TSS Portabel tss meter sinchetech

-

OKTAN METER OKTIS-2 ALAT UKUR OKTAN OKTIS2 JUAL ALAT UKUR OKTAN OKTIS 2.....

-

Jual Gas Detector Tube Draeger , Gas Detector Tube Draeger Indonesia Draeger Indonesia distributor